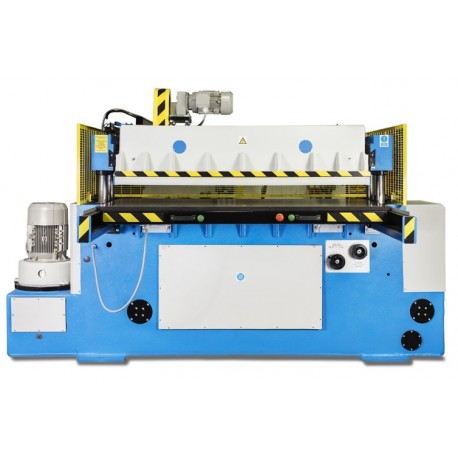

MECOX automatic gasket cutting machine

specification

| Maximum cutting force | 30 tons (up to 165 tons on special order) |

| Hammer dimensions | 400 mm x 400 mm (400 mm hammer or 500 mm hammer) |

| Table dimensions | 2180 mm x 600 mm |

| Engine power | 15 kW |

| Dimensions | 3025 mm x 2080 mm x 2030 mm |

| Libra | 5800 kg |

| DC Control | DC : 24 V |

| Pneumatic supply | 5 to 8 bar |

| Continuous adjustable cutting stroke | 5-100 mm |

| Max. Distance from table to hammer | 100 mm (200 mm without tooling) |

| Drive: | electric drive |

| Min / max power: | 0,5 / 15 kW |

| Electric supply: | 3x400 V; 50 Hz |

More Information

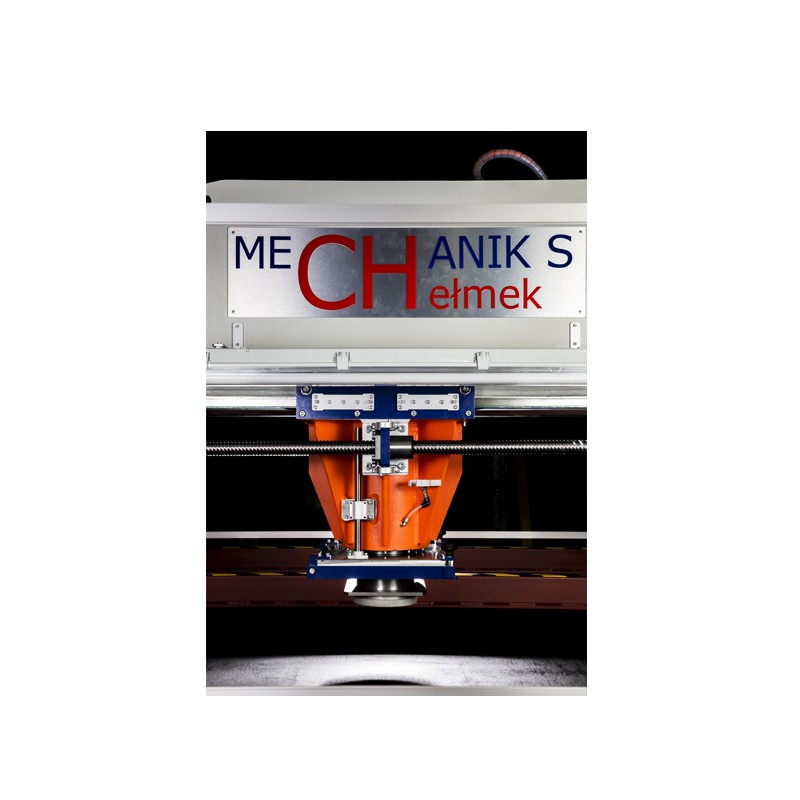

MECOX Electric Cutter

The MECOX machine is a modern, programmable cutter designed to cut various types of materials, from soft to medium-hard. Equipped with a gasket cutter, intuitive software, and advanced cutting capabilities, the machine finds application in various industries such as automotive, printing, packaging production, plastics processing, film, and paper industries.

Advantages of the MECOX machine:

- High cutting force of 30 tons (up to 165 tons)

- Intuitive programming with a touch panel

- High cutting precision of 0.02 mm (tolerance to be agreed upon)

- Precise cycle repeatability

- High speed operation

- Low consumption of consumables

- Very quiet operation (with direct drive)

- 1 mm margin between details

- margin between details < 1 mm,

- No hydraulic oil required

This device is ideal for those who value convenience and precision. MECOX allows you to set even the most accurate parameters, which will remain unchanged despite use. It presents a significant competition to hydraulic cutters, where the entire work focuses on actuators, which may not be able to reach certain positions correctly. Compared to mechanical solutions, the MECOX machine does not require the continuous purchase of new and exceptionally expensive components to improve work quality.

In the bridge cutter with a movable bridge, the required cutting stroke is determined by the sum of the thickness of the material being cut and the required clearance between the cutting knife and the material. It is not recommended to use knives of different heights.

We have implemented many modern solutions and functions in the MECOX machine, such as:

- All servo drives

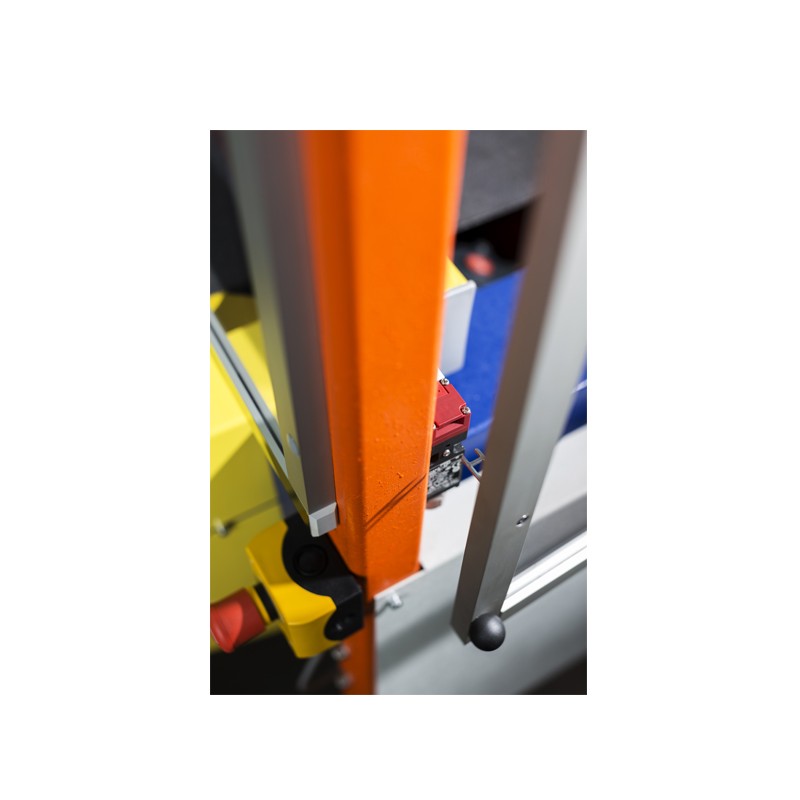

- Hammer movement performed by 2 ball screws

- Material feed realized by linear guides and ball screw

- Absolute measuring system ABS

- Real-time operation RTC

- Cooperation with barcode readers

- Automatic report generation

- Possibility of diagnostics and data exchange LAN

- Ability to exchange data EtherNet / IP (SCADA)

- Advanced system support (measurements, corrections, and fault detection)

- Ability to directly connect robots, e.g., packing or sorting robots.

We strive to ensure that our proposed solutions fully meet the needs of the enterprise We care about minimizing operating costs, so we have excluded the need to purchase additional tools and consumables.

Machines

Machines  Service

Service  Materials

Materials  Spare Parts for Rail Vehicles

Spare Parts for Rail Vehicles