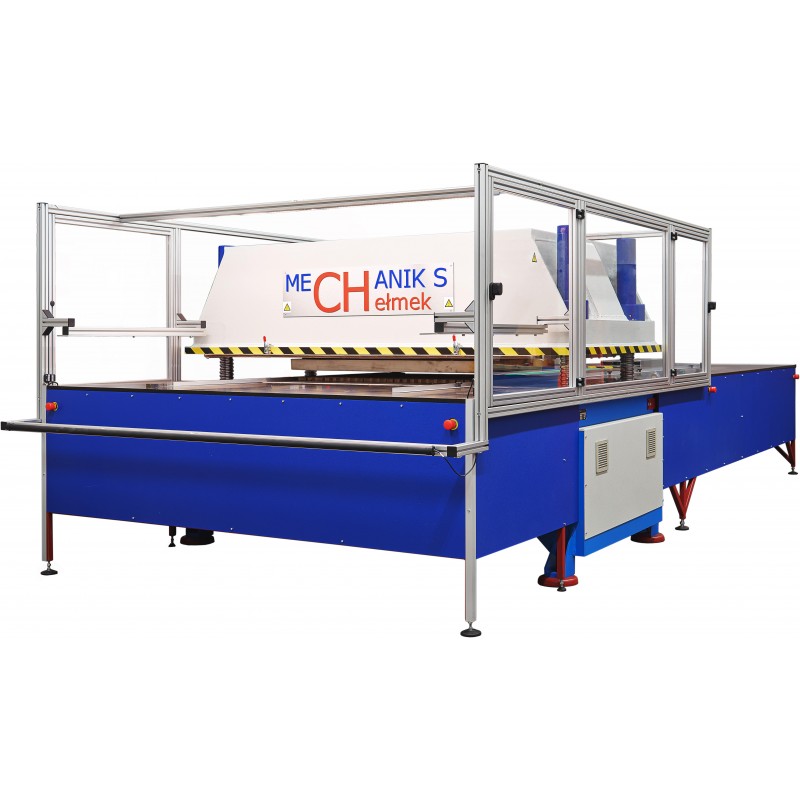

MECOX automatic electric cutting machine

specification

| Maximum cutting force | 30 tons (up to 165 tons on special order) |

| Hammer dimensions | 400 mm x 400 mm (400 mm hammer or 500 mm hammer) |

| Table dimensions | 2180 mm x 600 mm |

| Dimensions | 3025 mm x 2080 mm x 2030 mm |

| Libra | 5800 kg |

| Electric power supply | 3x400 V; 50 Hz |

| DC Control | 24 V |

| Pneumatic supply | 5 to 8 bar |

| Installed power | 15 kW |

| Continuous adjustable cutting stroke | 5-100 mm |

| Max. Distance from table to hammer | 100 mm (200 mm without tooling) |

| Drive: | electric drive |

| Min / max power: | 0,5 / 15 kW |

More Information

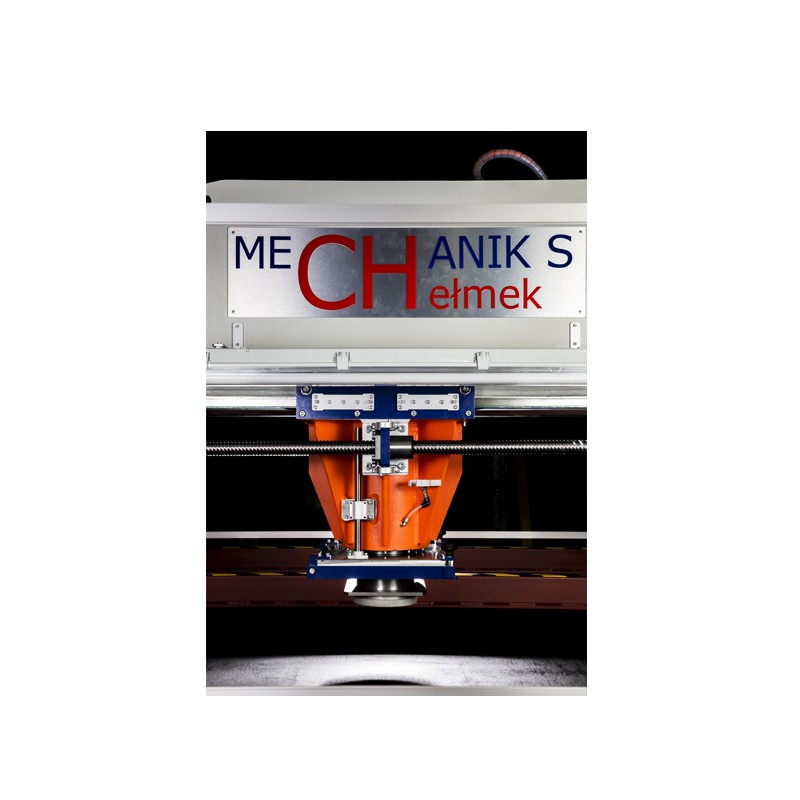

MECOX Electric Cutter

The MECOX machine is a modern, programmable cutter designed to cut various types of soft to medium-hard materials using cutting dies. This cutter can be applied across various industries including automotive, printing, packaging, gasket production, plastics processing, film, paper, and many others. Advantages of the MECOX machine:

- High cutting force ranging from 30 tons (up to 165 tons).

- intuitive programming with a touch panel

- High cutting precision of 0.02 mm (tolerance negotiable).

- repeatability of precise cycles

- work speed

- low consumption of consumable materials

- Very quiet operation (with direct drive).

- low power consumption

- repeatability of precise cycles

- No hydraulic oil

Its innovative construction, utilizing the technologies described below, has allowed the development of a modern machine with previously unattainable parameters for older types of cutters, such as hydraulic cutters.

For comparison, in hydraulic die cutters, pressing the die into the material is done by actuators, which, among other things, due to the medium used, do not allow for precise positioning. with notes on the use of a medium that is not available for position achievement. All kinds of mechanical solutions aimed at improving work parameters required the use of precise and very expensive components, and the desired effect was achievable only at the beginning of use and quickly deteriorated with the wear of these components.

In the bridge cutter with a movable bridge, the required cutting stroke is determined by the sum of the thickness of the material being cut and the required clearance between the cutting knife and the material. It is not recommended to use blades of different heights due to the possibility of errors in settings, although it is possible. In the case of using blades of different heights, for example, 24 mm and 32 mm, it is necessary to ensure easy and intuitive identification or to use equipment that eliminates possible errors during adjustment. Minor adjustments to the blade height due to wear can be made by authorized personnel.

We used many modern solutions and functions in the Mecox machine, such as:

- all servo drives

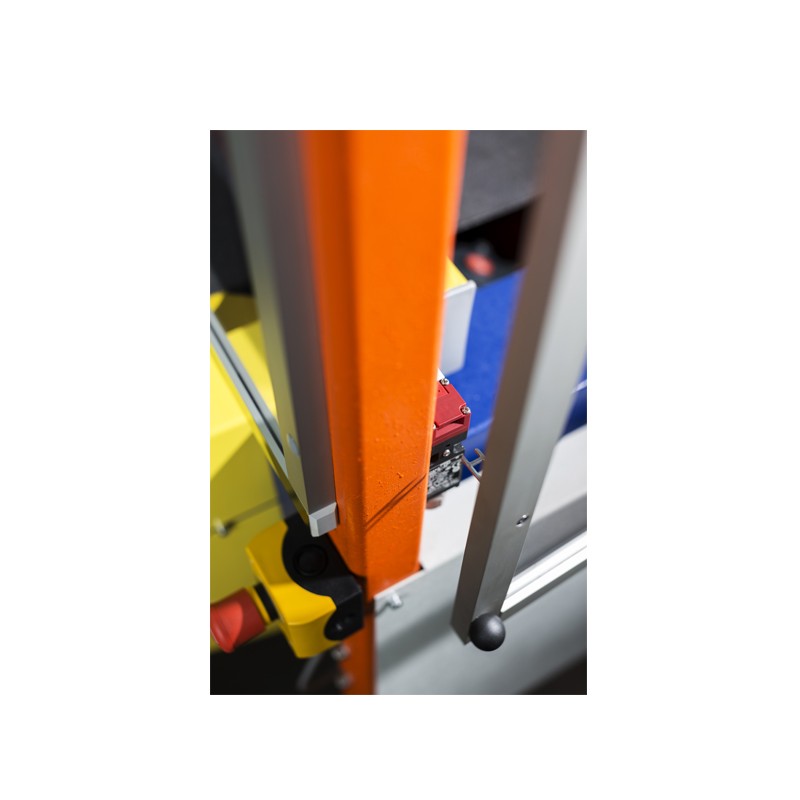

- hammer movement carried out by 2 ball screws

- material feeding done by linear guides and ball screw

- absolute ABS measurement system

- real-time RTC operation

- cooperation with barcode reader

- automatic report generation

- possibility of LAN diagnostics and data exchange

- possibility of EtherNet / IP data exchange (SCADA)

- support for advanced systems (measurements, corrections, and defect detection)

- possibility of direct connection of robots, e.g., packing or sorting robots

Thanks to this, we have gained extraordinary possibilities and functionality that can be used in many ways.

High quality components and the technology used significantly increased accuracy and, as a result, the wear of tools and consumables was reduced.

Machines

Machines  Service

Service  Materials

Materials  Spare Parts for Rail Vehicles

Spare Parts for Rail Vehicles