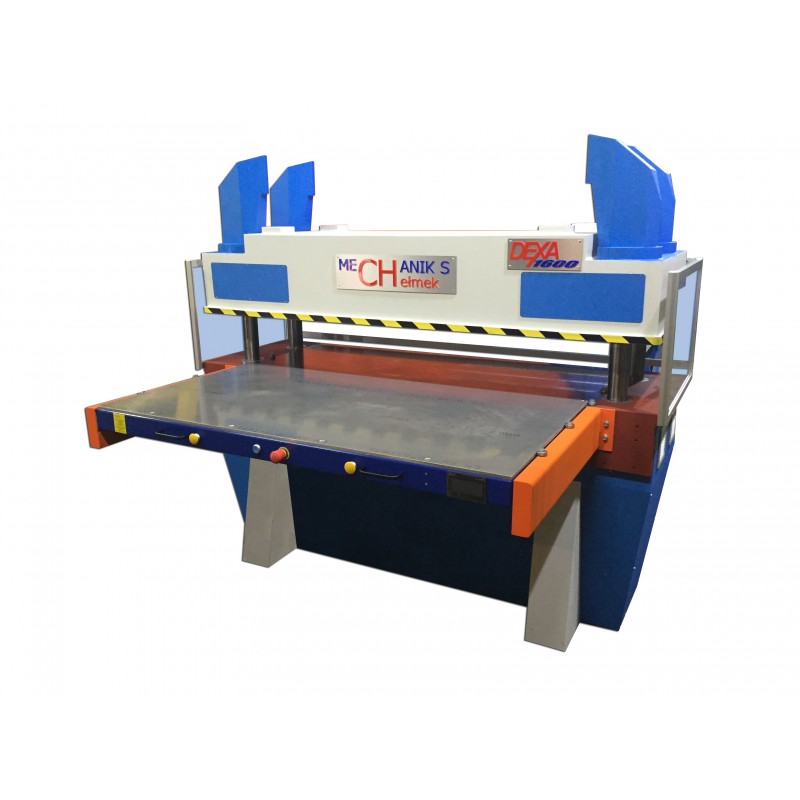

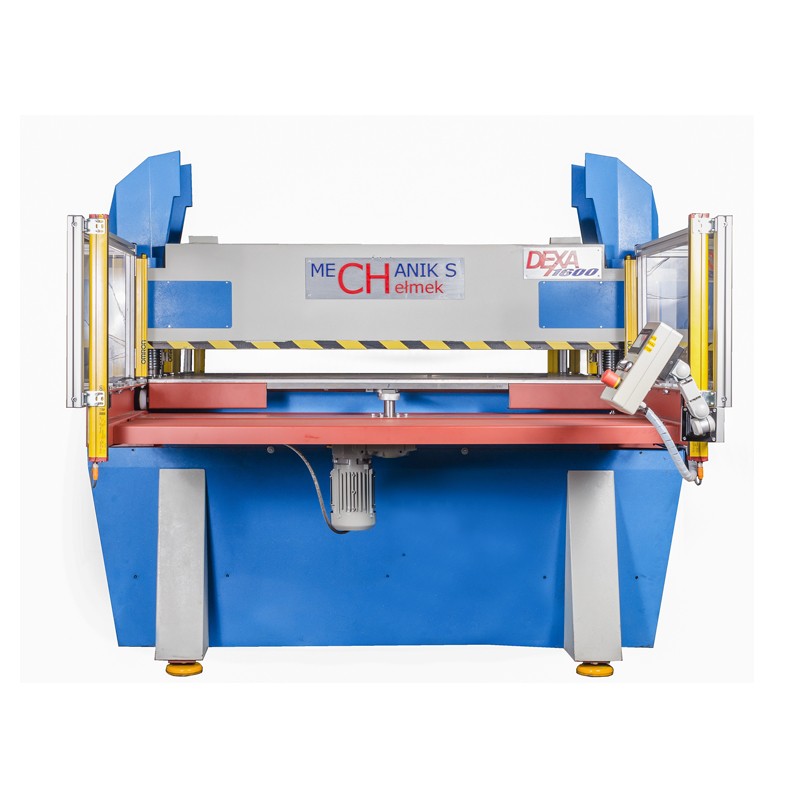

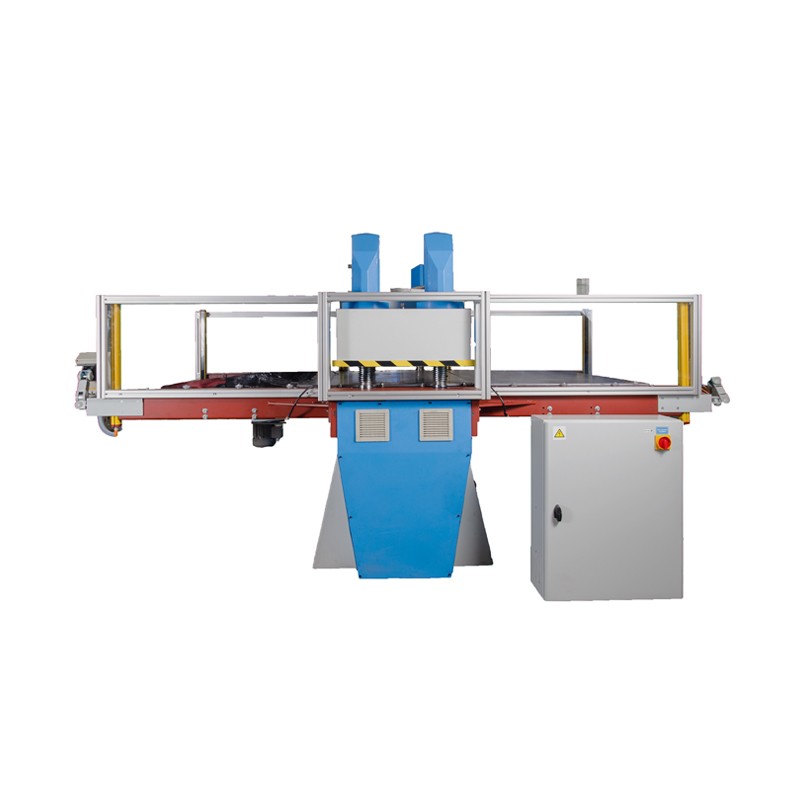

Economical DEXA 1600 bridge cutting machine with two tables

specification

| Table dimensions | 1600 mm x 650 mm |

| Dimensions | 2000 mm x 650 mm, height 1600 mm |

| Libra | approximately 3 tons |

| Pressure force | 50 ton |

| Stroke: | do 200 mm |

| Clearance: | do 400 mm |

More Information

In recent years, production companies using bridge cutting machines have shown a demand for modern machines that meet EU requirements regarding safety, noise levels, and environmental protection. These requirements also apply to economical machines, meaning those with low operating costs, lighter construction, and full versatility. In response to the above conditions, the “MECHANIK S” company created the DEXA 1600 cutting machine.

Years of experience in building and repairing machines have allowed us to combine the best features of bridge cutters, avoiding faulty and unreliable solutions. Modern design of DEXA 1600 allows for its reconstruction and expansion, creating entire production lines. For the needs of DEXA 1600, many variants of additional equipment have been designed, which can be purchased from “MECHANIK S” together with the machine or at a later date. It is also possible to design components according to the individual needs of the customer.

Example performance of the DEXA 1600:

- die for 4 details,

- 1 layer 2 mm,

- upper position 150 mm,

- lower position 50 mm,

- manual operation, manual feeding,

- number of details per shift – 10,800 pieces

Advantages of the cutter:

- high cutting force up to 50 tons,

- quiet operation,

- low power consumption,

- additional control panel,

- attractive price,

The DEXA 1600 cutter is a modern cutting machine that can be applied in many industries. The innovative design and additional equipment allow for perfect adaptation to your production needs. The use of modern technology has allowed us to develop a “speeding up” function of the machine as production increases, as well as the automation of the cutting process through the use of a feeder or receiver. We have prepared a special offer for customers for 2 versions of the machine – basic and advanced.

DEXA 1600P – basic:

- very quiet operation

- low power consumption

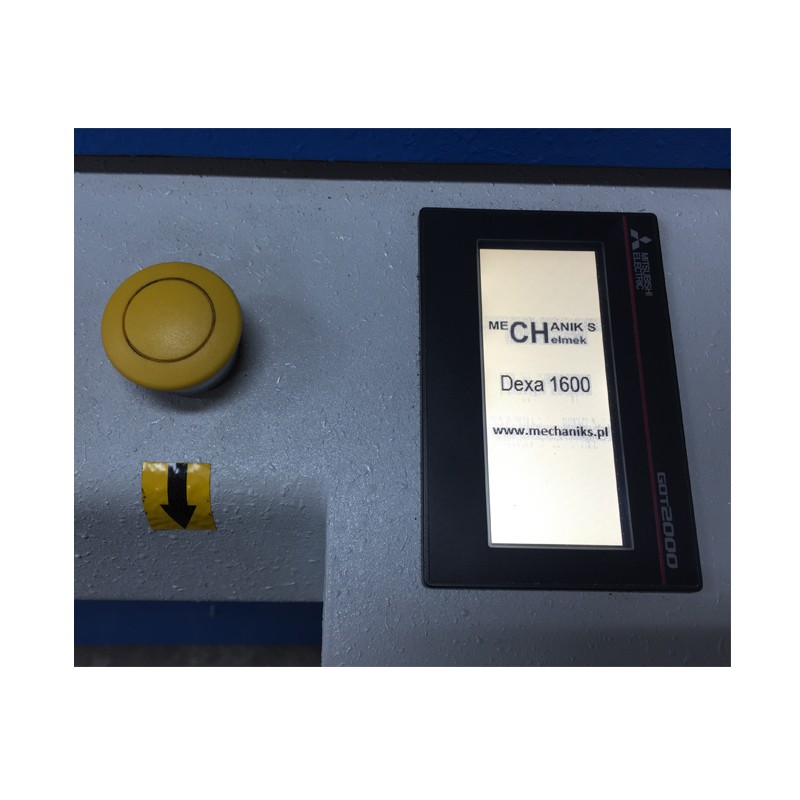

- touch control panel

- manual height adjustment (wheel)

- statistics functions (hits, working time, etc.)

- counting and subtracting functions

- mounts for attaching the receiver and feeder

- mounts for attaching safety curtains

- short delivery time

- attractive price

DEXA 1600Z – advanced

- very quiet operation

- low power consumption

- touch control panel

- height adjustment system (motor)

- replaceable aluminum hammer plate

- mounts for attaching the receiver and feeder

- mounts for attaching safety curtains

- full automation and expansion capability

- work area lighting in the front and back

- statistics functions (hits, working time, etc.)

- counting and subtracting functions

- diagnostics and reminders for maintenance

- automatic lubrication system

Additional equipment for both versions:

- manual or automatic feeder

- safety curtains

- automatic/semi-automatic feeder (only for version Z)

- replaceable steel hammer plate

- system for automatic moving of the base plate (only for version Z)

In the DEXA 1600 cutter, the working cycle of the hammer is carried out by a crank mechanism. This solution works well both for manual cutting and for serial production, allowing for uniform and fast operation of up to 800 cycles per hour.

The main engine’s proper operation is ensured by a reliable inverter drive from Mitsubishi, allowing precise stopping of the hammer in the desired position and adjustment of the working speed. The basic version of the DEXA 1600 cutter is equipped with a touch panel used to set operating parameters and read information. Between cutting cycles, the machine remains in standby mode, consuming minimal power, which significantly saves energy and reduces operating costs. The cutting height in the basic version is adjusted using a knob, while in the advanced version, it is done using buttons.

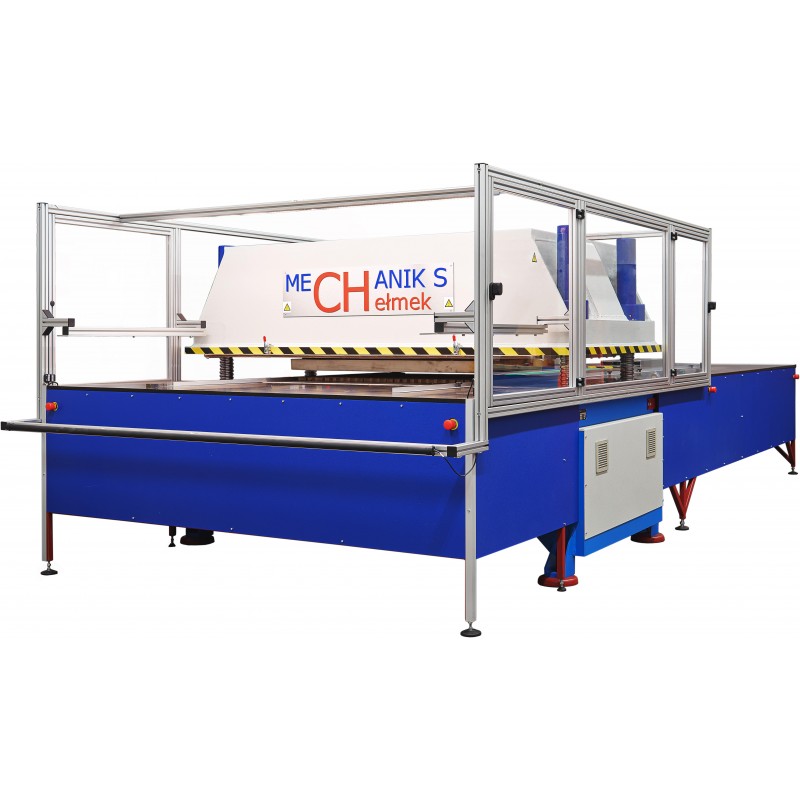

Version with a DOUBLE-SIDED MANUAL feeder.

Each machine is customized to meet the client’s needs, and we offer professional assistance and service.

Machines

Machines  Service

Service  Materials

Materials  Spare Parts for Rail Vehicles

Spare Parts for Rail Vehicles