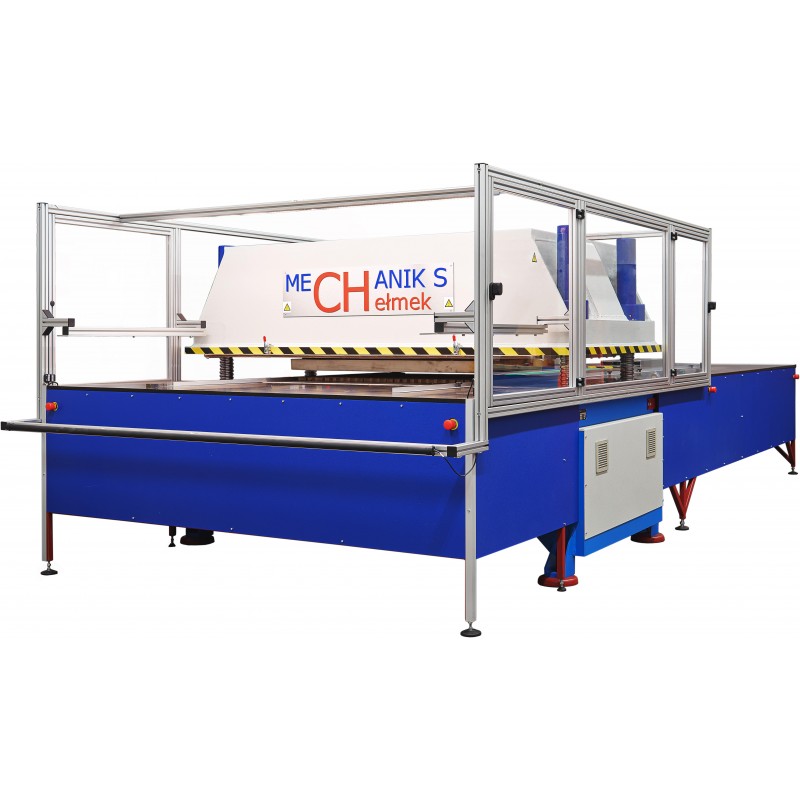

MSP 2000 with transport belt

specification

| Maximum cutting force | 100 ton |

| Hammer dimensions | 2000 mm x 1050 mm |

| Table dimensions | 2000 mm x 1050 mm |

| Libra | 7500 kg |

| Pressure force | 1000 kN |

| Cutting accuracy | 0,025 mm |

More Information

The MSP 2000 machine is a modern, precise die cutter used for cutting various soft materials up to medium-hard materials using polygraphic dies and steel strip.

In the MSP 2000 machine, we have implemented many modern solutions and features such as:

- all servo drives

- material feeding done by linear guides and ball screw

- absolute ABS measurement system

- real-time RTC operation

- cooperation with barcode reader

- automatic report generation

- possibility of LAN diagnostics and data exchange

- Ability to exchange data via EtherNet/IP (SCADA)

- Support for advanced systems (measurements, corrections, and defect detection)

- possibility of direct connection of robots, e.g., packing or sorting robots

Thanks to this, we have gained extraordinary possibilities and functionality that can be used in many ways.

MACHINE ADVANTAGES:

- high cutting force up to 100 tons

- high cutting precision 0.015 mm

- repeatability of precise cycles

- low consumption of consumable materials

- low power consumption

- work speed

- very quiet operation

- No hydraulic oil

EXAMPLE OF REAL EFFICIENCY:

- Manual feeder:

- 4 details per die

- 6 layers cut at 2 mm each

- Upper position 150 mm, lower position 52 mm

- Manually controlled automatic feeder

- 21,600 details per 1 shift (7.5 hours)

Automatic feeder:

- 16 details per die

- 3 layers cut at 5 mm each

- Over 150,000 details per 1 shift

POSSIBLE APPLICATION:

This cutting machine can be used in various industries such as:

packaging, printing, automotive, paper, gasket production, plastics processing and many others.

INNOVATIVE CONSTRUCTION

In hydraulic cutters, the die pressure on the material is achieved by actuators, which, among other reasons, due to the medium used, do not allow for precise positioning. with notes on the use of a medium that is not available for position achievement. All kinds of mechanical solutions aimed at improving work parameters required the use of precise and very expensive components, and the desired effect was achievable only at the beginning of use and quickly deteriorated with the wear of these components. Deviation requires frequent parameter corrections. Because our machine implements a new method of driving the working hammer, this increases work efficiency and allows for convenient, quiet execution of technological operations. The high quality of components and the technology used significantly enhances productivity, thus reducing tool and consumable material consumption.

The machine is suitable for cutting large-format elements from sheet material or rolls, both from single and multiple layers.

Years of experience and expertise in the production and repair of cutting machines have enabled the creation of a machine with outstanding parameters, unique construction, and an attractive price.

The MSP 2000 is the type of machine that excels in continuous operation (three-shift) as a reliable, fast, and accurate machine.ka i dokładna maszyna.

KISS CUTTING – The MSP 2000 machine allows for automatic cutting with kiss cutting.

Machines

Machines  Service

Service  Materials

Materials  Spare Parts for Rail Vehicles

Spare Parts for Rail Vehicles